Choosing the Right Stainless Steel Cavity Wall Ties for Masonry Work

On November 7, 2025

Comments Off on Choosing the Right Stainless Steel Cavity Wall Ties for Masonry Work

Choosing the Right Stainless Steel Cavity Wall Ties for Masonry Work

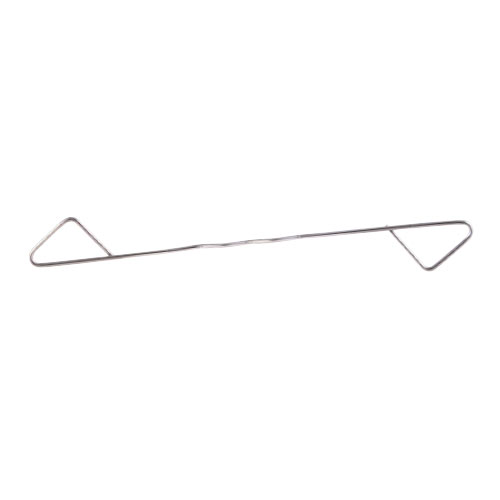

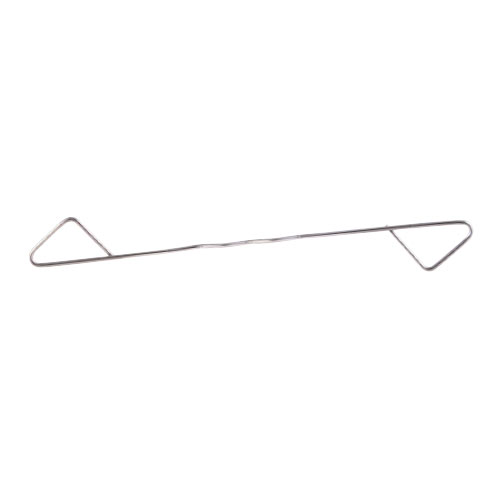

When you’re building or repairing a cavity wall, choosing the right wall ties is essential for safety, strength, and durability. Wall ties connect the inner and outer leaves of a cavity wall, helping the structure act as one solid unit. Poorly chosen or corroded ties can lead to cracking, damp, or even structural failure.

Why Use Stainless Steel Cavity Wall Ties?

Stainless steel cavity wall ties are designed for long-term performance in both domestic and commercial buildings. They resist rust and corrosion, making them ideal for areas exposed to moisture, sea air, or corrosive materials such as green oak. For tradesmen, this means fewer call-backs, reduced maintenance, and complete peace of mind that the job will last. Timco manufactures high-quality stainless steel cavity wall ties to meet the latest building standards, including Eurocode 5. Their tangle-free design makes them easy to handle on site, cutting down time and hassle.Timco Type 2 Wall Ties – For Three-Storey Builds

Timco Type 2 Stainless Steel Wall Ties are suitable for masonry cavity walls in domestic houses and small commercial buildings up to three storeys, or a maximum of 15 m in height. They’re made from A2 stainless steel for excellent corrosion resistance and can be used wherever moisture, chemicals, or certain timber species might cause rust. Sizes available:- 225 × 3.0 mm (for cavities 76–100 mm)

- 250 × 3.0 mm (for cavities 101–125 mm)

- 275 × 3.0 mm (for cavities up to 150 mm)

Timco Type 4 Wall Ties – For Two-Storey Projects

Timco Type 4 Stainless Steel Wall Ties are ideal for domestic houses and smaller commercial buildings up to two storeys, or 10 m in height. They’re also made from A2 stainless steel and share the same tangle-free design for easy site handling. Sizes available:- 200 × 2.3 mm (for cavities 50–75 mm)

- 225 × 2.3 mm (for cavities 76–100 mm)

- 250 × 2.7 mm (for cavities 101–125 mm)

- 275 × 2.7 mm (for cavities up to 150 mm)

Top Tips for Installing Wall Ties

- Check the cavity width before choosing your tie. Each size and type has a specific range to ensure proper embedment.

- Maintain at least 50 mm embedment in each leaf of masonry for a strong bond.

- Follow spacing rules – typically 2.5 ties per m² (900 mm horizontal × 450 mm vertical). Around window or door openings, tighten spacing to 300 mm vertically and 225 mm from the opening edge.

- Keep ties clean and level. Mortar on the surface can create a moisture bridge between leaves.

- Always use stainless steel ties in coastal or damp conditions to prevent corrosion.

When to Use Screw-In Frame Ties

While Timco’s Type 2 and Type 4 ties are built into the mortar joints, the screw-in frame tie offers an alternative for remedial work or fixing inner and outer leaves where new masonry isn’t being laid. These screw-in versions are handy for renovations or extensions that join new and existing walls.Wall Ties

-

TIMCO Wall Ties - Light Duty - Type 4 - A2 Stainless Steel - 200mm £38.66 ex VAT(£46.39 inc VAT)

-

TIMCO Wall Ties - Light Duty - Type 4 - A2 Stainless Steel - 275mm £89.16 ex VAT(£106.99 inc VAT)

-

TIMCO Wall Ties - General Duty - Type 2 - A2 Stainless Steel - 275mm

£159.99 ex VAT(£191.99 inc VAT)

TIMCO Wall Ties - General Duty - Type 2 - A2 Stainless Steel - 275mm

£159.99 ex VAT(£191.99 inc VAT)

-

TIMCO Wall Ties - General Duty - Type 2 - A2 Stainless Steel - 250mm £94.99 ex VAT(£113.99 inc VAT)

-

TIMCO Wall Ties - Light Duty - Type 4 - A2 Stainless Steel - 225mm

£35.66 ex VAT(£42.79 inc VAT)

TIMCO Wall Ties - Light Duty - Type 4 - A2 Stainless Steel - 225mm

£35.66 ex VAT(£42.79 inc VAT)

-

TIMCO Wall Ties - General Duty - Type 2 - A2 Stainless Steel - 225mm £65.41 ex VAT(£78.49 inc VAT)

-

TIMCO Wall Ties - Light Duty - Type 4 - A2 Stainless Steel - 250mm

£65.41 ex VAT(£78.49 inc VAT)

TIMCO Wall Ties - Light Duty - Type 4 - A2 Stainless Steel - 250mm

£65.41 ex VAT(£78.49 inc VAT)

Final Thoughts

Choosing the right stainless steel cavity wall ties is essential for any bricklayer, builder, or site manager. Timco’s Type 2 and Type 4 ranges offer proven reliability, high corrosion resistance, and full compliance with UK building standards.

For long-lasting strength in every wall, choose Timco stainless steel cavity wall ties from Fast Fixings Online - available in a full range of sizes and supplied in boxes of 250 for convenience on site.