Plasterboard Beading

Professional plasterboard beading solutions for clean edges, strong corners, and durable plaster finishes.

What Is Plasterboard Beading?

Plasterboard beading is used to reinforce, protect, and define edges, corners, joints, and movement points within plasterboard and internal plastering systems. These beads and accessories provide the structure needed to achieve straight lines, crisp finishes, and long-lasting results, especially in areas prone to impact or cracking.

At Fast Fixings Online, our plasterboard beading range covers everything from everyday drylining work to specialist applications. Whether you’re forming sharp corners, reinforcing joints, managing movement, or preparing surfaces for plaster or render, choosing the right bead makes a clear difference to the final finish.

Where Is Plasterboard Beading Used?

Plasterboard beads play a vital role in both residential and commercial interiors. They are commonly used in:

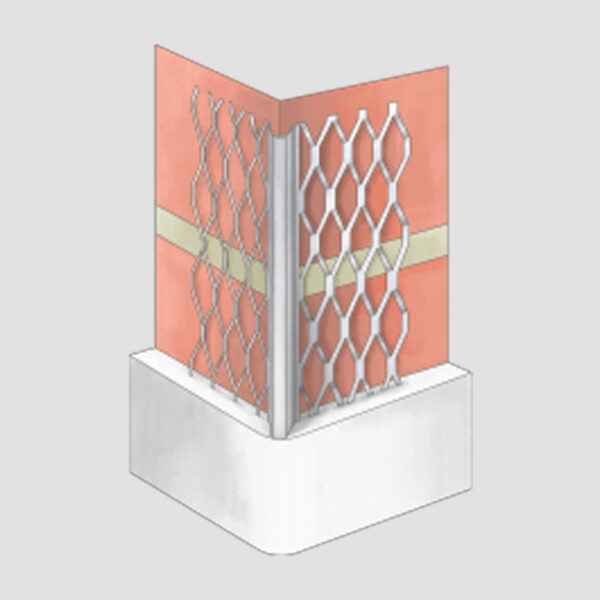

Corners and Edges

Corner beads and edge beads protect vulnerable plasterboard edges while helping maintain straight, consistent lines. Once embedded, they reduce chipping and improve durability in high-traffic areas.

Joints and Repairs

Drywall joint tape, corner tape, and mesh products reinforce board joints and patch repairs. They help prevent cracking and ensure plaster bonds properly across joins.

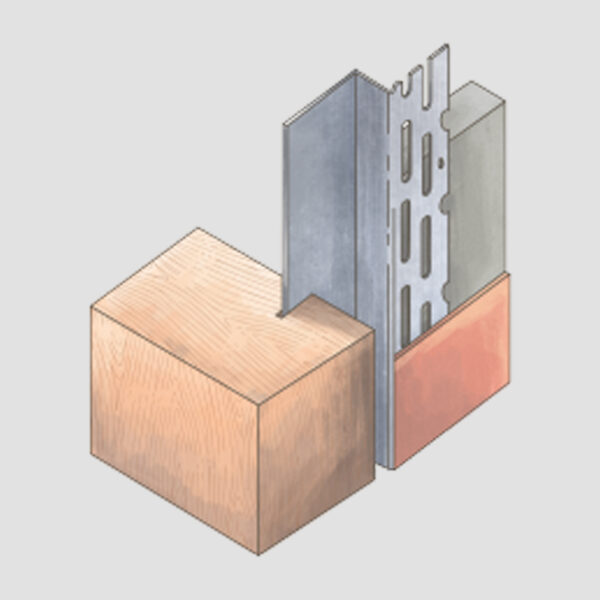

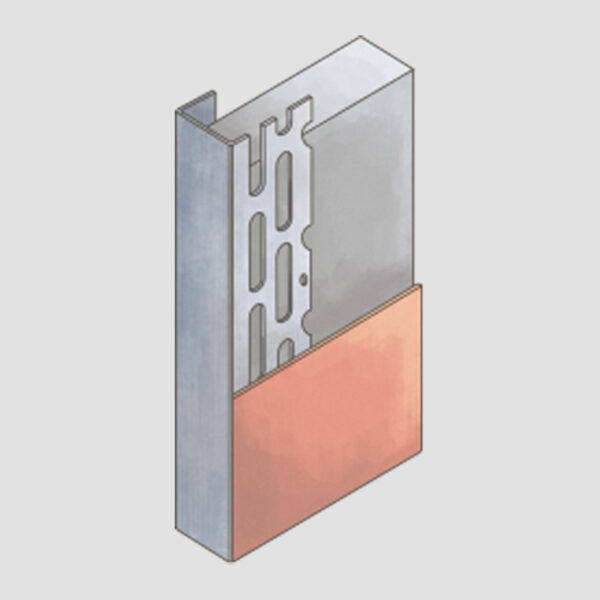

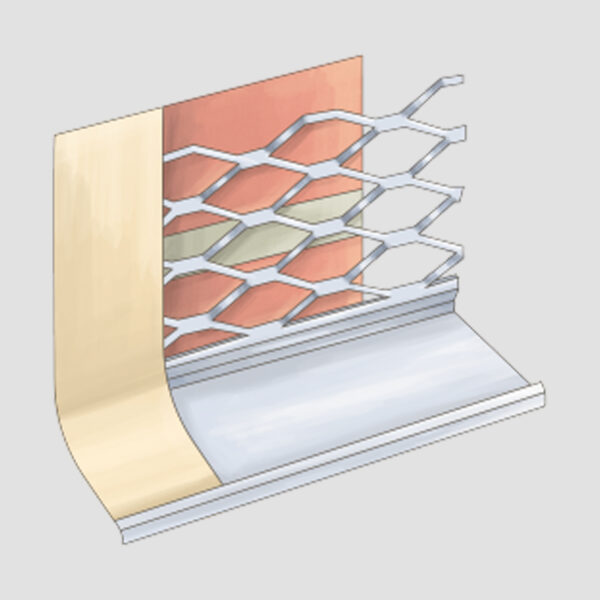

Stops, Reveals, and Transitions

Plaster stop beads and render stop beads create clean termination points where plaster meets windows, doors, ceilings, or other materials. They provide a neat, professional edge while protecting the plaster from damage.

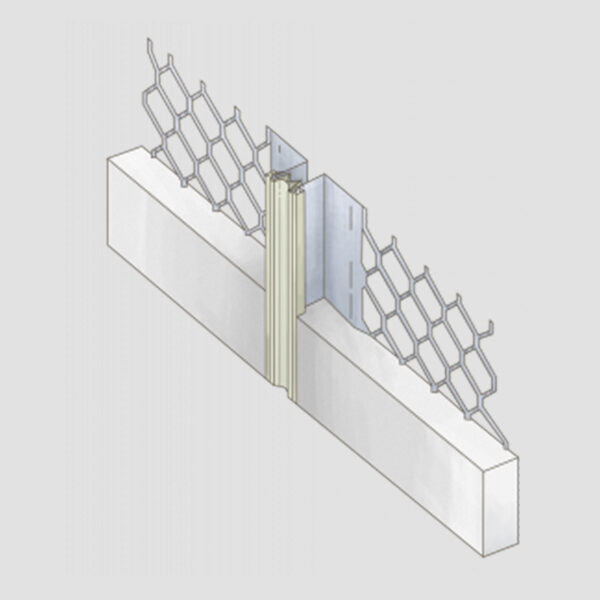

Movement Control

Movement beads allow plaster finishes to expand and contract naturally. They reduce cracking on larger wall runs, junctions, and areas where structural movement is expected.

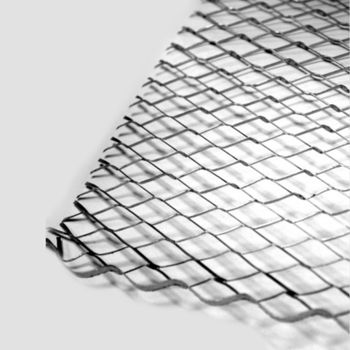

Reinforcement and Substrates

Expanded metal lath sheets, coils, rib lath, and alkaline resistant render mesh reinforce plaster and render systems. These products improve adhesion and provide a strong mechanical key, particularly on ceilings, partitions, masonry, or uneven backgrounds.

Types of Plasterboard Beading We Stock

Our plasterboard beading range includes:

- Corner Beads – For sharp, protected internal and external corners

- Edge Beads – To reinforce plasterboard edges and reveals

- Arch Beads & Architrave Feature Beads – For curved features and decorative finishes

- Drywall Feature Beads – For modern detailing and clean lines

- Plaster Stop Beads – To form neat plaster terminations

- Render Stop Beads – For controlled render edges where required

- Movement Beads – To manage expansion and contraction

- Drywall & Corner Tape – For jointing, repairs, and corner reinforcement

- Expanded Metal Lath (Sheet & Coil) – For plaster reinforcement and brick reinforcement

- Rib Lath Sheets – For stiffened plaster keying on ceilings and partitions

- Alkaline Resistant Render Mesh – For reinforcing render and plaster systems

Available in galvanised steel, stainless steel, and uPVC, our range suits internal applications as well as exposed or moisture-prone environments where required.

Why Use Plasterboard Beading?

Clean, Straight Finishes

Plasterboard beads act as a guide during installation, helping achieve straight edges and sharp lines with less effort and rework.

Improved Strength and Durability

By reinforcing corners, joints, and edges, beading reduces cracking, chipping, and long-term damage.

Better Crack Control

Movement beads, mesh, and lath products absorb stress within plaster systems, helping finishes remain intact over time.

Faster, More Consistent Installation

Pre-formed profiles and self-adhesive tapes speed up installation and reduce the need for corrective work.

Versatile Across Systems

Plasterboard beading works with plasterboard, blockwork, internal plaster, thin coat systems, and selected render applications.

Choosing the Right Bead

Different applications require different profiles, materials, and fixing methods. Galvanised beads suit most internal environments, while stainless steel and uPVC options are recommended for damp, exposed, or high-moisture areas. Always follow manufacturer guidance for installation, overlap, and fixing to achieve the best result.